Oil Rotary Vacuum Pump

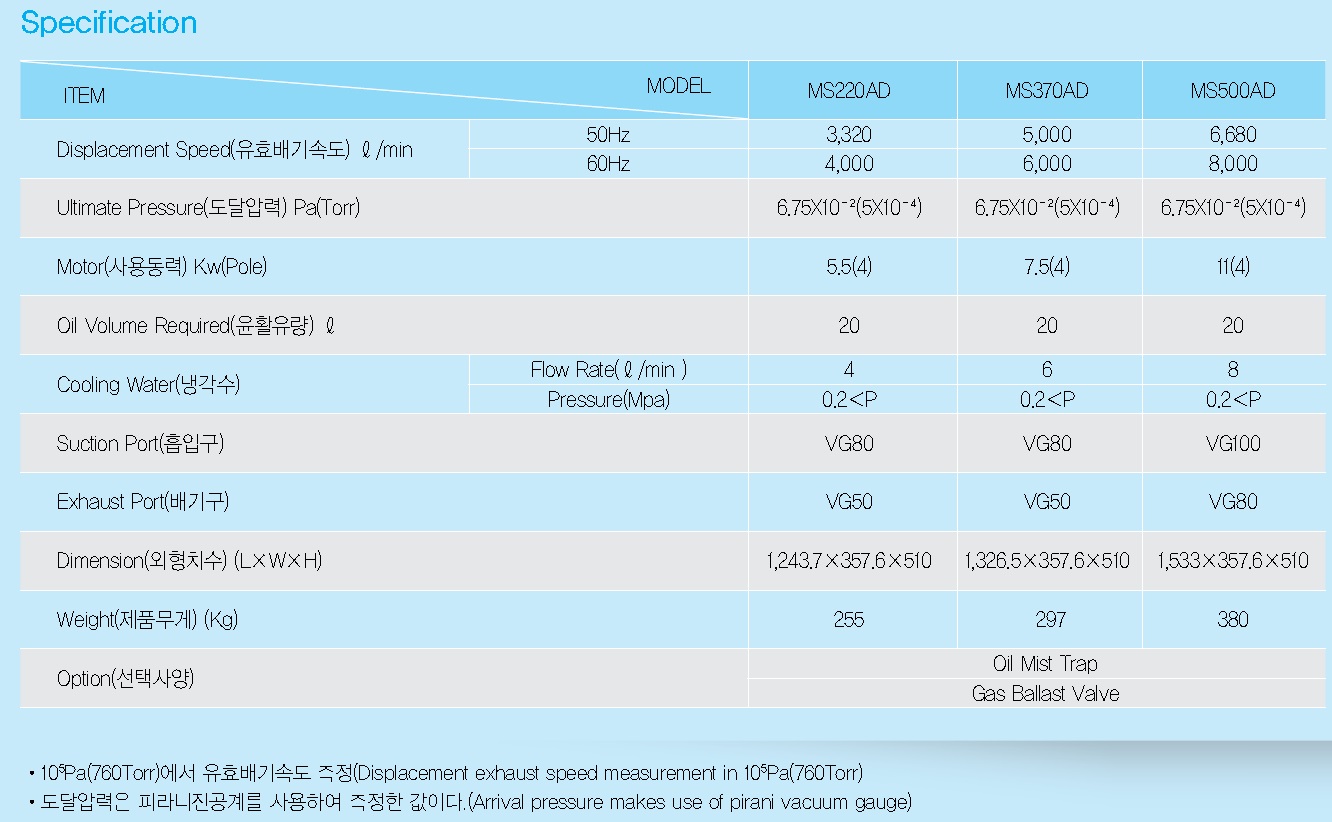

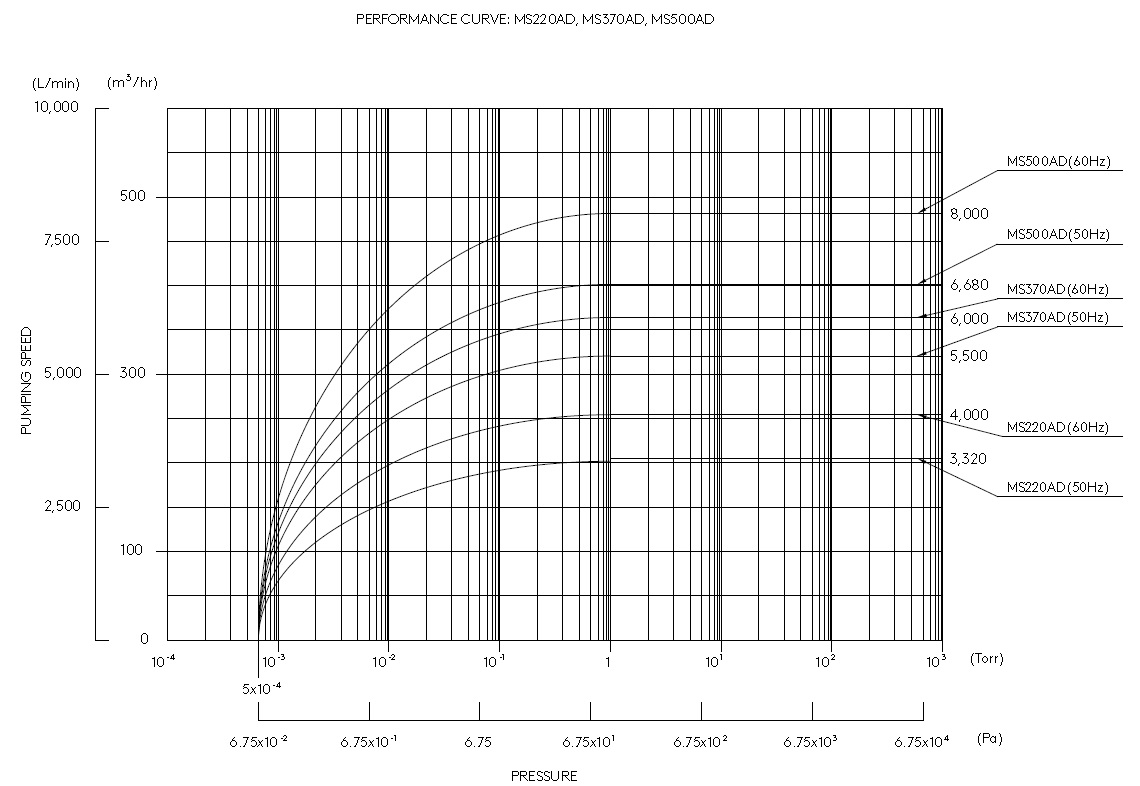

- - Displacement speed(60Hz) : 3320 ~ 8000 ℓ/min

- - Ultimate Pressure : 1 Stage : 3 x 10-2 Torr

2 Stage : 5 x 10-4 Torr

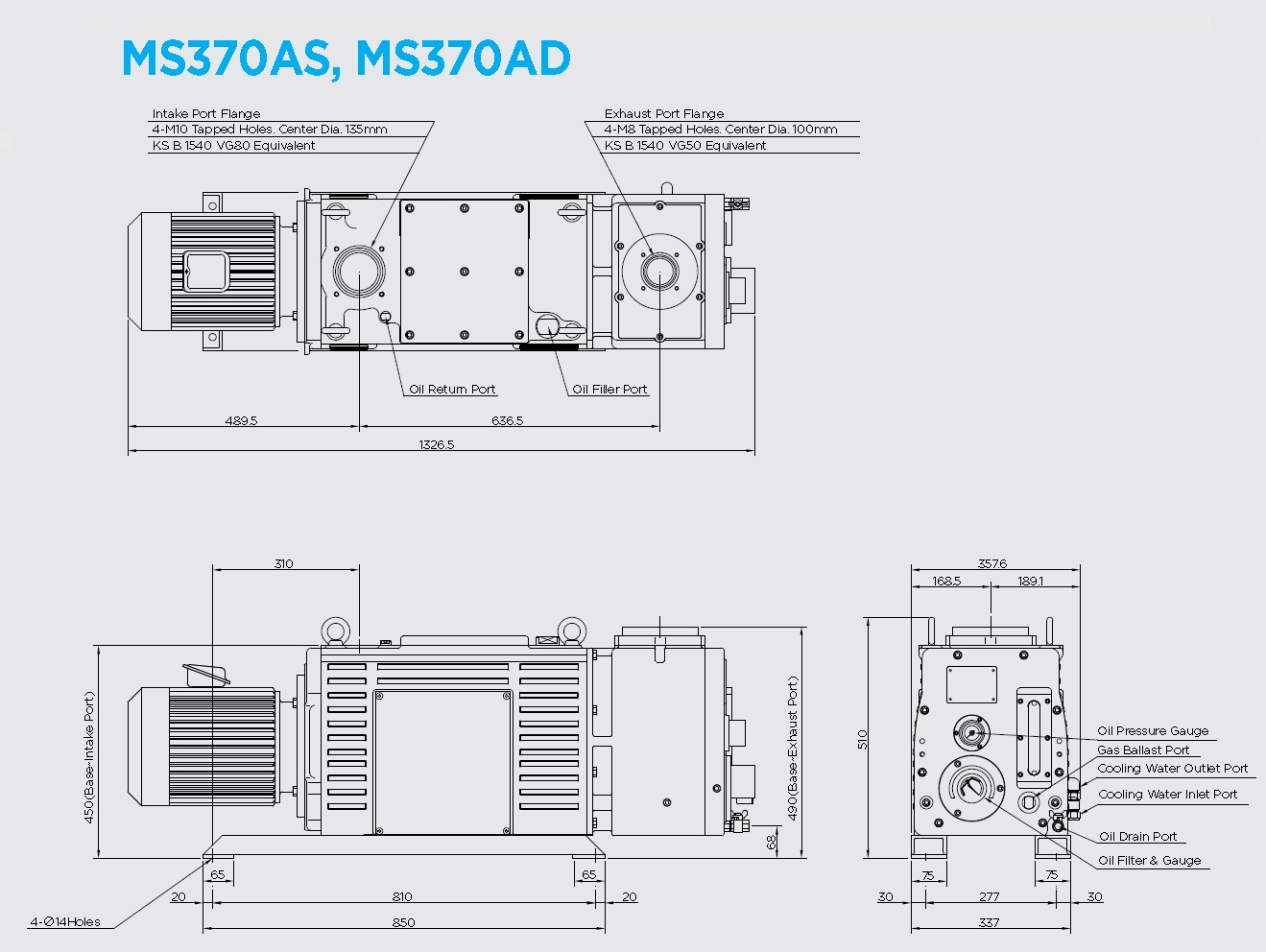

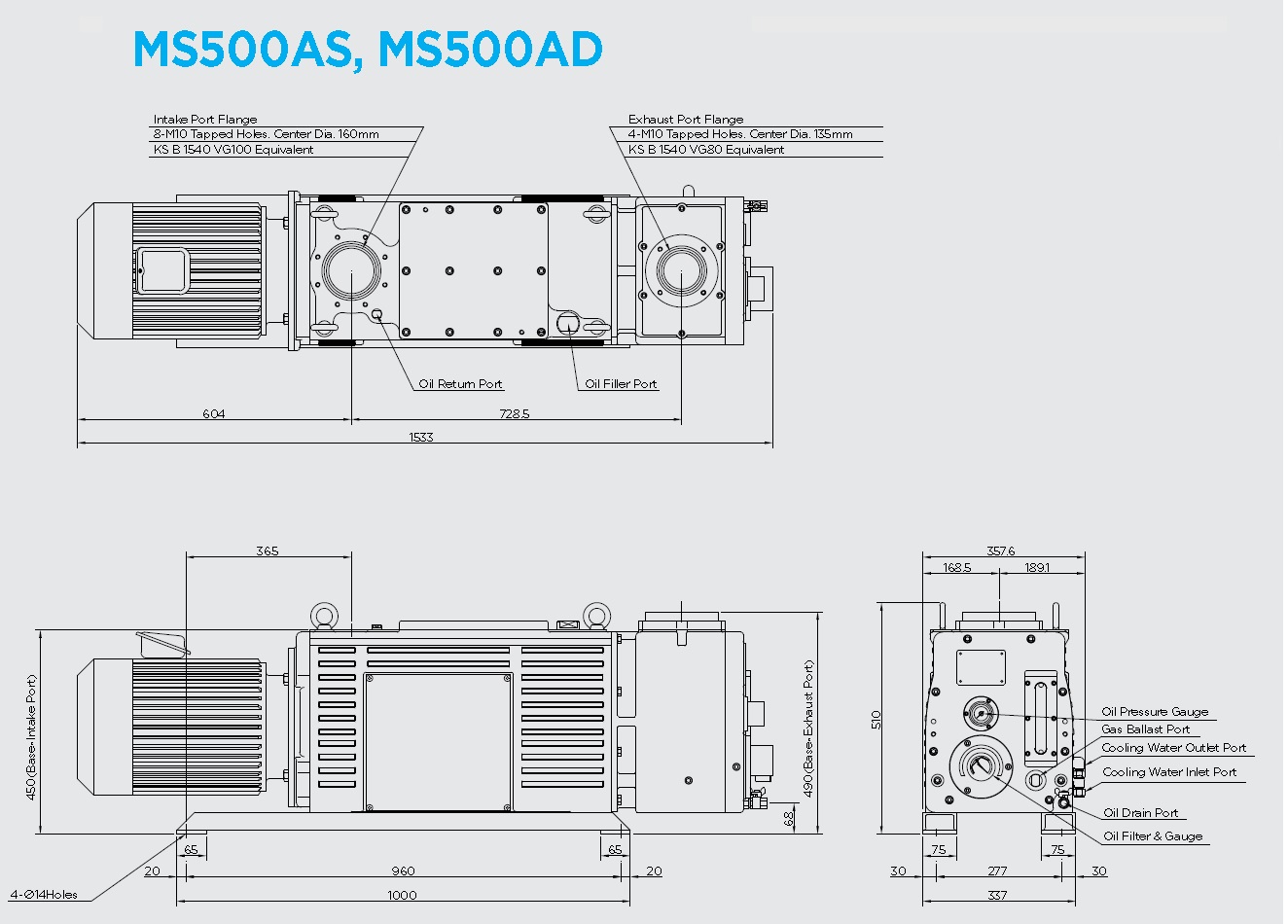

Oil rotary vacuum pump (Direct vane type vacuump pump :MS Series MSP 1Stage and 2Stage) MS series type pump is oil rotary vacuum pump and designed to be used widely for all vacuum industries in both laboratory and industrial facilities. As shown in fig, this vacuum pump consists of pump body, including pump housing, rotor being eccentric in cylinder of motor oil case, the front and rear covers of cylinder, and parts related to it. This pump is bases on the principle that pump and motor are connected by flexible coupling, and than, even rotor of pump turns as motor turns. As rotor rotates, two vanes in groove of vane of rotor turn, making contact with the internal side of cylinder by centrifugal force. The gas thus drawn in through the intake port with dirt. Trap passes the open airing isolation valve and streams into the pump chamber. As vanes being rotated pass near the intake aperture, the gas in confined between two vane and then, turn toward exhaust valve. Passing exhaust valve, gas starts to be compressed, and the fully- opens exhaust valve and is exhausted through exhaust port. The inside and vane of cylinder, vane and vane of rotor and moving parts will be lubricates, and also, oil to be given to cylinder for security of seals.

- •The stable cooling effectBecause the cooling water is flowing between the first cylinder and theoil casing and the cooling effect is superior. (Continuous running ispossible at low vacuum)•Stable vacuum pressureThe oil pump supplies proper amount of oil inside the cylinder accordingto vacuum pressure degree, which causes very small amount ofchanging vacuum pressure compared to operation hour.•The small vibrationBy realizing directly connected driving that the geometric design isapplied to minimize the eccentric rotation, it shows very small vibration incompared to piston type having the same displacement.•Weight reduction, and a miniaturized vacuum pumpIntegration of the cylinder and the casingMinimize the installation area ofthe original format.•Small noiseBy ideally designing the valve catcher situated at the exhaust valve, werealized very small noise.•Oil pressure gauge and oil filter are equipped.Filtered oil without strange material is supplied inside the oil pump andalso, you can know when the filter will be changed through the filterpressure guage.•Excellent compatibilityIt is manufactured in order that the one-stage pump and the two-stagepump are mutually compatible.•Automatic control oil supply volumeIt properly control oil supply according to pressure inside the cylinder.•This pump is designed for easy maintenance.Inside extension connected with casing cover ensures the proper space.Also, it is designed in order to easily separate oil and humidity in order tominimize oil flow even during operation.•Simple treatment and easy overhaulThe casing has several side covers at pump’s side and top for easycleanup, which has everyone easily disassemble and clean up it.•ISO standards applicationAccording to using ISO standards motor application, anyone can shiftand change the motor easily at anyplace and anytime.•Oil Mist Trap are possible to take easily-OptionOil Mist Trap is designed for less oil smoke, noise and oil consumption.•Gas ballast valve are possible to be easily installed-Option.It can take an adoption gas ballast valve in order to reduce condensationof moisture.•Affixed the oil circulation safety deviceWhen the oil filter is blocked, automatically, the oil circulation safety deviceimmediately supplies the oil which is not filtered to the lubricating parts.